VACUUM DECAY TEST OR PRESSURE RISE TEST

ACOUSTIC LEAK TESTING

INFRARED LEAK INSPECTION TESTING

TRACER GAS TESTING

ULTRASOUND LEAK DETECTION

PRESSURE DECAY LEAK TEST

BUBBLE TEST LEAK

SMOKE LEAK DETECTION

AIR INFILTRATION TESTING

BOOK AN APPOINTMENT

Reliable Leak Detection with Vacuum Decay Test

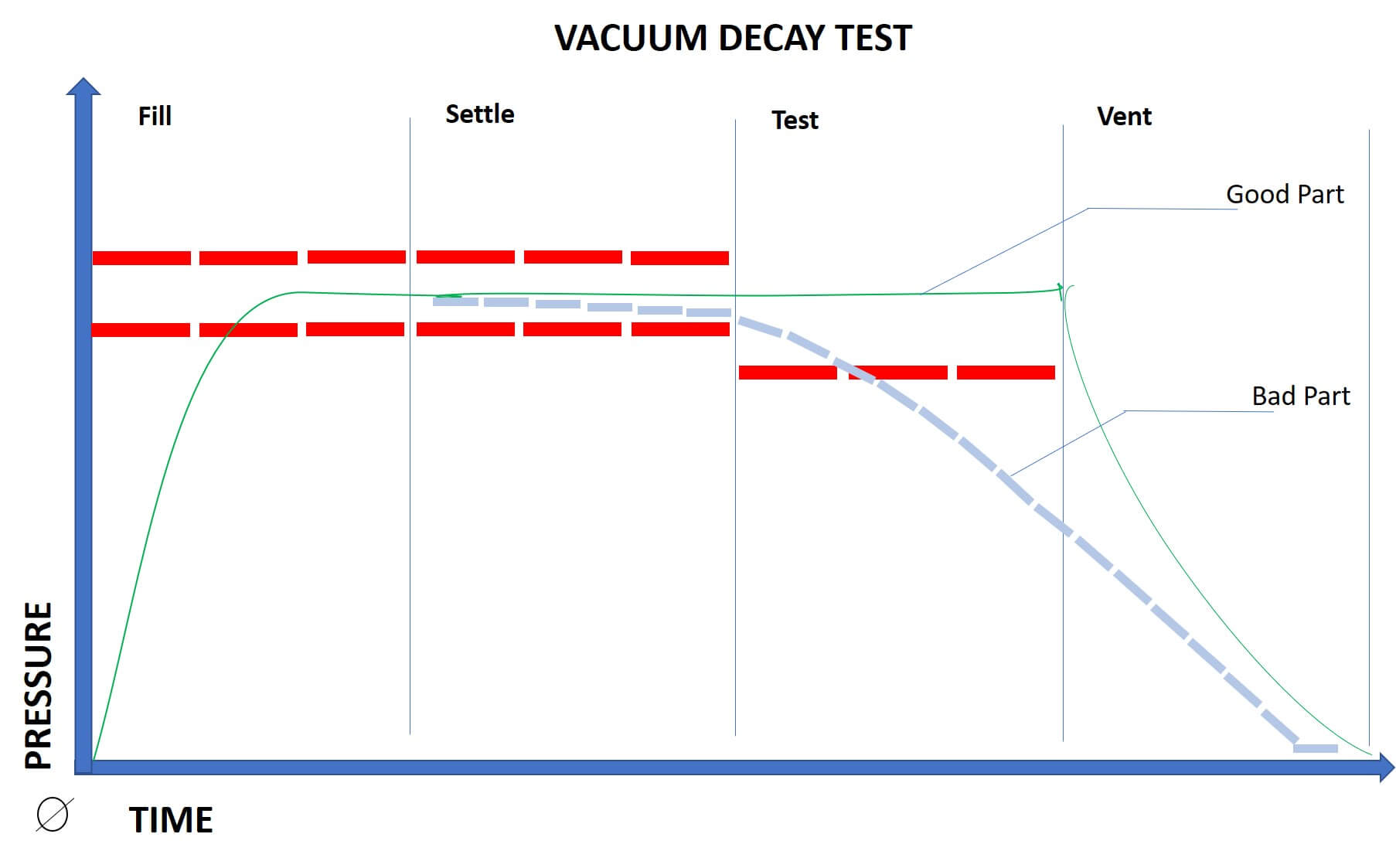

The Vacuum Decay Test is a proven non-destructive method for detecting leaks with high accuracy. This technique measures the pressure difference between atmospheric pressure and the test sample under vacuum conditions. Even small leaks can compromise the integrity of equipment, leading to potential failures. By identifying leaks early, the Vacuum Decay Test helps ensure the reliability and safety of sealed systems.

Ensuring System Integrity with the Pressure Rise Test

The Pressure Rise Test is a reliable method for detecting leaks in sealed systems by measuring pressure changes over time. This test works by creating a vacuum within the system and monitoring any increase in pressure, which indicates the presence of a leak. It is widely used in industries requiring airtight seals, ensuring product reliability and preventing potential failures caused by undetected leaks.

Precision Leak Detection with Vacuum Decay Leak Test Services

Vacuum Decay Leak Test Services provide a highly accurate, non-destructive method for detecting leaks in sealed systems. This testing technique measures pressure variations under vacuum conditions, identifying even the smallest leaks that could compromise system integrity. Ideal for industries requiring airtight enclosures, Vacuum Decay Leak Testing ensures product reliability, enhances quality control, and prevents costly failures.

Advantages of Vacuum Decay Test

- Accurately determines leak rates using pressure or vacuum measurements.

- Extremely precise in detecting even the tiniest leaks.

- Applicable for both pressure and vacuum environments.

- Capable of reporting pressure or flow loss for precise diagnostics.

- Simple yet highly effective non-destructive leak detection method.

How It Works ?

The Vacuum Decay Test measures the leak rate by monitoring pressure changes over time. When a component is sealed in a vacuum chamber, any air escaping from the part causes a rise in pressure, indicating a leak. This method allows for precise leak detection and can be performed on components before manufacturing to ensure product integrity and quality.

HOW LONG DOES THE LEAK DETECTION PROCESS TAKES?

Considering this we have developed the Inspection Techniques which would consume the least/no time from the customer which would be from 0-6 hours.

HOW MUCH DOES THE PROCESS COST?

As the leading service provider for Leak Detection Services in all over Middle East, we are happy to provide the best prices for our clients. Please contact the company to know the Best price for you!

You can also choose an annual contract to get the least possible prices and cover your resources Leak Proof.

ARE YOU SURE THAT YOU CAN FIND THE LEAKS?

We at Leak Plus with more than seven Inspection Techniques are well ready to mitigate any types of risks during Inspection.

WE provide 100% CASHBACK GUARANTEE in case the leak is not identified.